Introduction

Witnessing your once-reliable diesel engine struggling with blow-by can be disheartening. Blow-by, the leakage of combustion gases past the piston rings, not only diminishes engine performance but also emits harmful emissions. This guide will delve into the intricacies of blow-by in diesel engines and equip you with comprehensive solutions to rectify the issue, restoring your engine’s optimal functionality and preserving its longevity.

Image: www.wikihow.com

Explaining Blow-By in Diesel Engines

Blow-by is an inevitable consequence of diesel engine operation, primarily due to the high combustion pressures and temperatures involved. As the piston moves within the cylinder, a small amount of combustion gases escapes past the piston rings, entering the crankcase and ultimately polluting the engine oil with soot and other contaminants. While some degree of blow-by is normal, excessive blow-by can lead to a range of detrimental effects.

Consequences of Excessive Blow-By

Left unchecked, excessive blow-by can manifest in various undesirable consequences:

- Reduced engine power and efficiency due to the loss of compression pressure

- Increased fuel consumption as the engine struggles to compensate for the power loss

- Increased emissions as combustion gases escape into the atmosphere

- Rapid contamination of engine oil, reducing its lubricating properties and necessitating frequent oil changes

- Premature wear and tear of engine components due to increased friction and heat

Identifying the Root Causes of Blow-By

Diagnosing the root causes of blow-by is crucial for implementing effective repairs. Common culprits include:

-

Worn or damaged piston rings: These rings are responsible for sealing the combustion chamber, preventing blow-by. Over time, they can wear out or become damaged, compromising their ability to contain combustion gases.

-

Worn or glazed cylinder walls: The cylinder walls provide a smooth surface for the piston rings to seal against. When the cylinder walls become worn or glazed, the rings may not be able to form a proper seal, leading to blow-by.

-

Incorrect piston ring installation: If the piston rings are not installed correctly, they may not function properly, allowing combustion gases to escape.

-

Excessive cylinder pressure: In certain cases, excessive cylinder pressure can overwhelm the piston rings, causing blow-by. This can be caused by a variety of factors, such as a malfunctioning turbocharger or an overly aggressive tune.

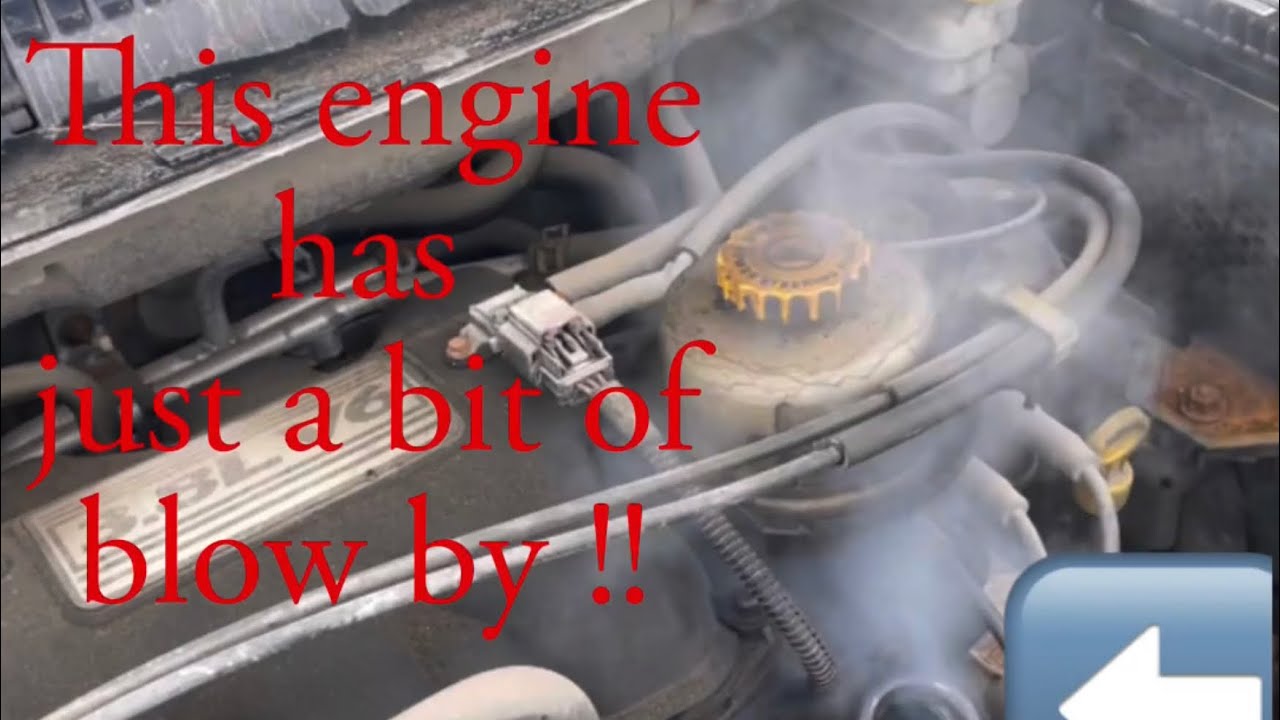

Image: www.youtube.com

Comprehensive Solutions to Fix Blow-By

Addressing blow-by in a diesel engine requires a comprehensive approach, involving:

-

Replacing worn or damaged piston rings: Replacing the piston rings with new ones is the most effective way to seal the combustion chamber and prevent excessive blow-by.

-

Honing cylinder walls: If the cylinder walls are worn or glazed, honing them will restore their smooth surface, allowing the piston rings to create a proper seal.

-

Correctly installing piston rings: Following the manufacturer’s instructions and using the proper tools will ensure that the piston rings are installed correctly, reducing the risk of blow-by.

-

Addressing excessive cylinder pressure: If excessive cylinder pressure is the root cause of blow-by, the underlying issue must be identified and resolved. This may involve repairing a malfunctioning turbocharger or adjusting the engine’s tuning.

Prevention is Key

While blow-by is an inherent characteristic of diesel engines, implementing preventive measures can minimize its severity and extend the engine’s lifespan:

-

Regular maintenance: Adhering to recommended maintenance schedules, including oil changes and filter replacements, ensures that the engine is operating in optimal condition, reducing the likelihood of blow-by.

-

Avoid engine overloading: Operating the engine within its specified load capacity prevents excessive cylinder pressure that can overwhelm the piston rings and cause blow-by.

-

Properly warming up the engine: Allowing the engine to reach operating temperature before applying significant loads reduces wear and tear on engine components, minimizing the risk of blow-by.

How To Fix Blow By In A Diesel Engine

Conclusion

Restoring and maintaining optimal performance in a diesel engine plagued by blow-by requires a comprehensive understanding of its causes and effective solutions. By replacing worn or damaged piston rings, honing cylinder walls, installing piston rings correctly, and addressing excessive cylinder pressure, you can effectively eliminate blow-by and restore your engine’s power and efficiency. Preventive maintenance, including regular servicing, avoiding engine overloading, and proper warm-up procedures, will further minimize blow-by and extend the engine’s lifespan, ensuring continued reliable operation.